The Pick fill seal machine is important for manufacturers. When they break down, it can hurt production and profits. This guide helps you fix common problems quickly. It shows you how to find and solve issues step-by-step. By using these tips, you can:

- Reduce delays.

- Keep product quality high.

- Keep your work moving smoothly.

I have cover fixes for sealing problems, filling errors, and machine breakdowns. This guide will help you get your seal packing machine working again fast. By, choosing a Pouch packing machine manufacturer like adroitmachinery you can achieve what you have to in no time with proper customer support. Contact us now for any efficient packaging solutions.

How a Pick Fill Seal Machine Works

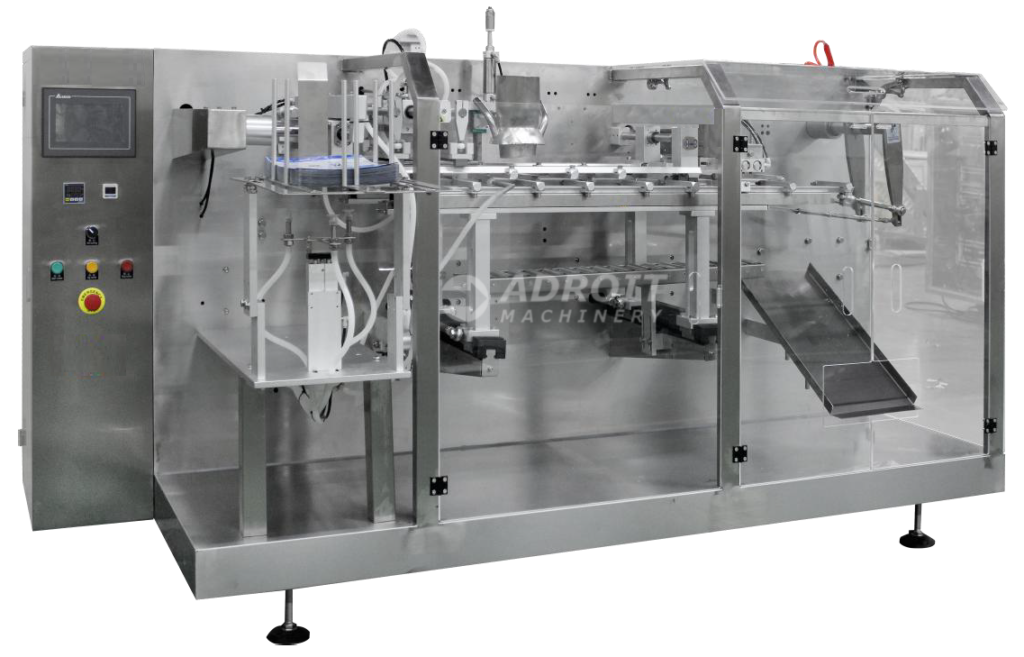

A Pick Fill Seal (PFS) machine is a smart packaging system. It’s also called a form-fill-seal (FFS) machine. Many industries use it. The machine works in three steps:

- Pick: It grabs empty pouches.

- Fill: It puts the product in the pouch.

- Seal: It closes the pouch tightly with heat.

Key Components

The key components of a PFS machine include:

- Pouch feeder.

- Pick and place mechanism.

- Filling system.

- Sealing system.

- Conveyor system.

- Control system.

Detailed Working Process

The basic working process of a pouch packing machine typically involves 8 key stations:

1. Bag Giving: Bags are fed from a magazine and transferred to a rotary table.

2. Date Coding: Printing of date or batch codes.

3. Bag Opening: Vacuum caps open the bags, with detection for proper opening.

4. Product Filling: Measured product filling using various methods.

5. Gas Flushing (optional): For modified atmosphere packaging.

6. Initial Heat Sealing: First sealing of the bags.

7. Secondary Heat Sealing: Ensures strong, airtight closure.

8. Forming and Output: Cold pressing and automatic output of finished pouches.

Suggested Read:

Common Issues with Pick Fill Seal Machine

Premade Pouch Pick Fill Seal Machine often has problems with pouches. The pouches may not feed or open right. This can happen for several reasons:

- Things stuck in the hose.

- Air or vacuum valve problems.

- Worn-out vacuum pads.

- Dirty sensors.

If pouches don’t open well, check for:

- Sagging bags.

- Wrong loading.

- Filter issues.

Sealing Defects

Pouch seals often have problems in the fill seal packing machine. This can happen for a few reasons:

- Sealing bars are too hot.

- Pressure is wrong.

- The sealing bar surface is scratched or dirty.

To avoid seal issues:

- Center bags in the grippers.

- For vertical seals, check the forming tube backstop.

- Make sure the film is the right distance from the forming tube.

Operational Hiccups

Here’s a simplified version using shorter sentences and simpler words:

The filling sealing machine may not start or reset right sometimes. This can happen for a few reasons:

- Power problems.

- Safety issues.

- Low air pressure.

Before using the machine:

- Make sure all doors are closed.

- Check that the emergency stop is off.

- Ensure there’s enough air pressure.

The printer or film might also have problems. This often happens when parts are broken or not set up right.

To keep the machine working well:

- Do regular upkeep.

- Use it carefully.

Suggested Read:

Troubleshooting Pick Fill Seal Machine Problems

Premade Pouch Pick Fill Seal Machines can have problems. These issues can slow down packaging. It’s important to know common problems and how to fix them. This helps keep work moving smoothly. It also helps make sure products are high quality.

Pouch Feeding and Opening Issues

Pouches often don’t feed or open right. This can happen for a few reasons:

- Things stuck in the hose.

- Air valve problems.

- Dirty sensors.

To fix this:

- Check vacuum pads work well.

- Load bags correctly.

- Clean your machine often.

Sealing Defects

Leaky pouches can hurt your product’s quality and how long it lasts. This often happens because:

- The sealing bar is too hot or cold.

- The pressure isn’t right.

- The sealing bar is scratched or dirty.

- The bags aren’t centered properly.

To keep your seal packing machine working well:

- Check its parts often.

- Clean the sealing parts regularly.

Mechanical and Electrical Issues

The machine might not start or restart correctly. This can happen for a few reasons:

- Power problems.

- Safety system issues.

- Not enough air pressure.

Before using the machine, always check:

- The power supply.

- Safety systems.

- Air pressure.

Suggested Read:

Maintenance Tips for Your Premade Pouch Pick Fill Seal Machine

Keep your pouch filling machine in good shape. Clean it often. This stops dust and leftover bits from building up. Use air spray and clean cloths to wipe it down. Check seals and gaskets closely. Look for signs of wear like worn belts or odd sounds. Regular care helps the machine work well and last longer.

Lubrication and Calibration

Proper lubrication reduces friction and prevents wear. Use the recommended lubricant type and amount. Regularly calibrate your fill seal packing machine to keep it accurate and efficient. This improves product quality and reduces waste.

Preventive Maintenance Schedule

Establish a routine maintenance schedule that includes daily, weekly, and monthly tasks:

• Daily: Inspect seals and sensors, and lubricate moving parts.

• Weekly: Perform thorough cleaning, and verify printer/sealing bar operation.

• Monthly: Assess mechanical alignment, and replace high-wear components.

Suggested Read:

When to Call a Pick Fill Seal Machine Manufacturer

Your pick fill seal machine may have big problems sometimes. These can be too hard to fix yourself. When this happens, call the maker of the machine. Mamata Machinery Limited says machine makers can help with tricky parts. These include control systems and how the machine works with other equipment. The makers know these machines very well. They can find and fix problems fast. This helps avoid long and expensive shutdowns.

Performance Optimization

Want to improve your machine’s performance? Need to change its packaging? Talk to the maker “Adroit Machinery” – contact us today. We know how to:

- Make production faster.

- Make packaging more accurate.

- Handle new product types.

- Makers can help your machine work better for your changing business needs.

Upgrade and Customization Needs

Your packaging needs may change over time. You might want to upgrade or customize your pick fill seal machine. It’s best to contact the machine’s maker for these changes. They can offer solutions that work well with your current setup. The manufacturer can also keep your machine running smoothly. They can help add new features or adjust the machine for different pouches or products.

Suggested Read:

Conclusion

Fixing your pick fill seal machine takes careful steps. Follow this guide to find and fix common problems. Always be safe. Check your machine’s manual. Keep good records of fixes and upkeep. With time, you’ll get better at spotting issues quickly. Regular care helps avoid breakdowns and makes your machine last longer. These skills will keep your machine running well. This means better work and better products.