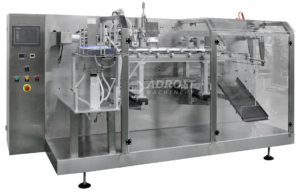

Premade Pouch Pick Fill Seal Machine

A premade pouch pick fill seal machine is an automated system designed to efficiently package products in pre-made pouches. In comparison to other equipment in the field, this machine is highly automated as well as versatile. It automates some steps such as feeding empty bags from a magazine or hopper, filling them precisely using different types of fillers and sealing them shut to create tamper evident packs. In many industries today, several companies are going for these machines because they are reliable and cost-effective too.

What it Does?

The automatic standby pouch filling sealing machine have 3 steps:

- Pouch Handling: The machine picks pre-made pouches from a magazine or feeder.

- Filling: The product is accurately filled into the pouch using various filling mechanisms like augers, cups, or weighers depending on the product type (liquids, powders, granules).

- Sealing: Once filled, the pouch is sealed shut using a heat sealing process to create a tamper-evident closure.

Applications

Premade pouch pick fill seal machine is also knowns as PFS machines are commonly used in various industries including:

- Food & Beverage

- Personal Care

- Pharmaceuticals

- Pet Food

What are the benefits of using it?

There are many benefits of using it but. Here are 5 benefits that you can’t avoid it:

- Efficiency: It automates the packaging process, thereby increasing production speed and reducing reliance on manual labor.

- Accuracy: Every pouch is filled in a consistent and precise manner.

- Versatility: It can accommodate a variety of pre-made bag styles and sizes.

- Hygiene: Usually, it is made of stainless steel for easy cleaning and maintaining cleanliness.

- Reduced Material Waste: Some machines are designed with features to cut down on material consumption during pouch forming.

Basic Machine Features

The automatic pick fill seal pouch packing machine has 8 features:

- Stainless Steel Construction

- Simple, Clean and Robust Design

- Pouch Pickup by Vacuum Suction Cups

- Pouch Detection before Filling

- PLC Controlled Functionality

- Digital Temperature Controller

- Easy & Quick Pouch Change Over

- Meet Electrical & Safety Standard

Model Types

| Model | AM-210 | AM-260 |

|---|---|---|

| Bag Width* | 90 to 210mm | 150 to 260mm |

| Bag Length* | 110 to 330mm | 150 to 400mm |

| Packing speed** | Up to 40 bags/min | Up to 40 bags/min |

| Power | 4KW 50Hz | 4.5KW 50Hz |

| Voltage | 440V | 440V |

| Air consumption | 0.5m³ | 0.7m³ |

| Suitable to fill | Liquid, Powder, Granule, Paste with different filling system | |

| Station* | 6 to 8 | |

| Type Of Pouch | Premade pouches Three Side Seal Stand-Up Pouch Zipper Pouch Spout pouch | |

| Material | Product contact area is Stainless steel [SS304/SS316] Other area is Stainless steel, Aluminum etc. Lower structure inside is mild steel with painted | |

Note: *we can give as per customer requirement.

**As per filling range and product.