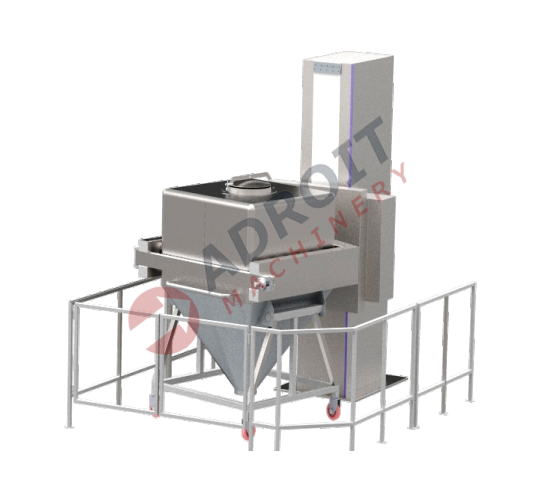

Bin Blender

Available Capacity: 25 kg to 500 kg batch size.

Application

IBC Bin blender / Conta blender is used for mixing different components of powders with powders, powders with granules and granules with granules in the production process in the pharmaceutical industry. The machine is provided with such functions as automatic lifting, mixing, lowering, etc. It can handle various sizes of bin for mixing operation.

Working process

Push and tight the bin into the arm. Lift the bin to the mixing height. Bin lifted by hydraulic system. Automatic mixing will carry out according to the set time, rotation speed and other data. Due to symmetrical axis of the bin forms an angle with the arm, it makes three-dimensional movement in the closed bin, achieving the best mixing effect. After the mixing, the bin completes vertical home positioning. After that, lower the bin and complete the mixing process or raise the bin to dispensing position. Loose the bin from rotary arm and push out the bin to the next process.

Salient features

- In compliance with cGMP

- Fully Automatic Operation through PLC & HMI.

- All Product contact parts SS 316 & non contact parts SS 304

- Interchangeable various sizes of bin on same machine for mixing operation.

- Hydraulic system for raising and lowering of IBC bin.

- Three-dimensional movement in the closed bin, achieving the best mixing effect.

- Butterfly valve at the discharge of bin and trolley for easy mobility.

- 21CFR Part 11 compliance with process data records and multi level password.