Are you a pharmaceutical manufacturer? Do you want to make your packaging process faster and easier? Consider using a Pick Fill Seal machine. It keeps products safe, intact, and legal. Efficient packaging is essential for drug-making and shipping.

The filling sealing machine is a new technology. This machine makes packaging easier. It’s accurate, fast, and versatile. It helps meet the high standards of the pharmaceutical industry.

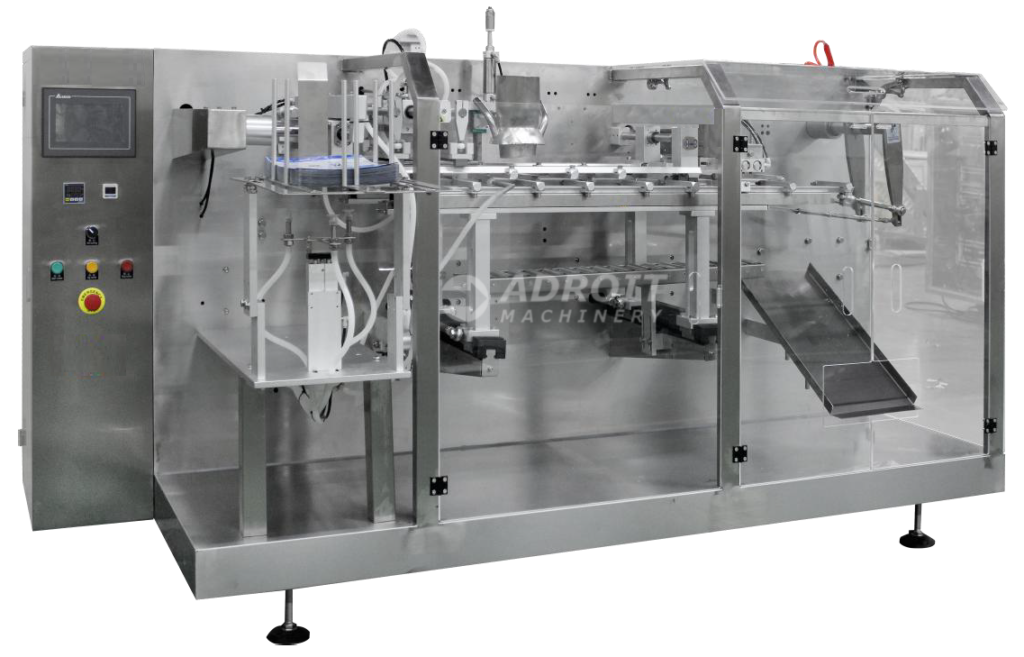

Have you ever thought, about the right pharmaceutical packaging suppliers? If you don’t choose the proper company for your packaging solutions you’ll seriously get into trouble. By choosing the AdroitMachinery you ensure you’re the priority of a medicine packaging company and eliminate all risks. This sounds crazy but we provide efficient pharmaceutical packaging solutions – like no one, contact us today.

This article shows how the pouch packing machine is improving packaging. They make products better and production faster.

What is pharmaceutical packaging?

Drug packaging is important for medicines. It protects drugs from damage and keeps them effective. This special packaging helps keep medicines safe, of good quality, and easy to use

Protection and Preservation

Pharmaceutical packaging protects medications from things that can make them less effective. PVC is a popular material for blister packs because it keeps things out and is easy to shape. This protects drugs from:

- It’s easy to break things when you’re not careful.

- Things like light, moisture, and air affect the environment.

- Contamination from external sources.

Information and Compliance

Pharmaceutical packaging is a key way to communicate important information. This includes information for patients and healthcare professionals. As Pharma Packaging Solutions points out, packaging provides:

- Clear dosage instructions.

- Important product warnings.

- Expiration dates and batch numbers.

Safety and Anti-Counterfeiting Measures

Drug safety is important. Good packaging for pharmaceuticals helps protect consumers. Modern packaging often includes:

- Child-resistant features to prevent accidental ingestion.

- Tamper-evident seals to ensure product integrity.

- Serialization for traceability and to combat counterfeit drugs.

Suggested Read:

The Importance of Pharmaceutical Packaging

Pharmaceutical packaging is important for keeping medications safe. It protects them from damage during shipping and storage. This ensures that patients get their medicine in good condition.

Packaging also helps to keep medicines effective. It protects them from things like light, air, and moisture. This is especially important for medicines that need special storage.

Information and Safety

Pharmaceutical packaging does more than just protect medicines. It also gives important information to patients, doctors, and government officials. Clear labels on the packaging give patients important information.

They tell patients how much to take, what side effects to watch for, and how to store the medicine. This helps patients use their medicines safely and correctly.

Safety features like tamper-proof seals and child-resistant caps are also important. These features help prevent accidental swallowing and keep the medicine safe. It’s very important to protect children and others who might be in danger.

Efficiency and Innovation

Modern packaging machines are changing the pharmaceutical industry. The fill seal packing machine is one example. These machines make packaging faster and cheaper.

They also help to ensure accurate dosing and reduce waste. The Premade Pouch Pick Fill Seal Machine is a good example. It can package liquids, powders, and other medications.

The pharmaceutical industry is changing, and packaging for medicines is also changing. New materials and designs are improving medicine packaging. These improvements help solve problems like fake medicine.

They also make medicines easier to use and safer. Working with a good packaging company can help pharmaceutical companies achieve these goals.

Suggested Read:

Benefits of Using a Pick Fill Seal Machine for Pharma Packaging

The pharmaceutical industry needs packaging that is accurate and efficient. Pick fill seal machines can automate the entire packaging process.

This makes production faster and increases output. These machines also fill and seal packages very precisely.

This ensures consistent quality and reduces waste. Pharmaceutical companies can use Pick Fill Seal machines. These machines can help them make products more efficiently and with high quality.

Enhanced Hygiene and Safety

Pick fill seal machines are important for pharmaceutical companies. They have enclosed systems that keep products clean. This helps prevent contamination.

The machines are also automated, so there is less human contact with the products. This makes them safer. These machines help companies package products safely and cleanly.

Versatility and Cost-Effectiveness

Pick Fill Seal machines are very versatile. They can package many different types of medicine, like pills, powders, and liquids. These machines can use bottles, pouches, or sachets.

This means you can package many different products without needing many different machines. Premade Pouch Pick Fill Seal machines are even more flexible.

They can use pouches that are already made. This saves money on materials and labor. In the long run, these machines can save a lot of money for pharmaceutical companies.

Pick Fill Seal machines are very useful for modern pharmaceutical packaging. They are versatile and efficient.

Suggested Read:

How Does PFS Machine Work?

The PFS machine is a three-in-one packaging solution. It picks, fills, and seals medicine. It’s a very useful machine for the pharmaceutical industry.

The Picking Process

The journey starts with picking. The PFS machine chooses pouches or containers from a storage area. This machine picks things consistently and helps avoid mistakes.

Precision Filling

After picking, the containers go to the filling station. The filling machine can fill many things. It can fill liquids, powders, granules, and solids. The machine uses special technology to measure the right amount of product. This is very important in the medicine industry.

The Sealing Process

The final step is sealing the filled containers. Use a heat sealer to close the pouch. This keeps the product safe and clean. This is important for medicine companies.

Many modern PFS machines have extra features. Some can print or emboss date codes or lot numbers. Others can settle the product or flush gas for modified atmosphere packaging.

Suggested Read:

Applications of PFS Machines in Pharmaceutical Packaging

Precision and Consistency in Medication Packaging

Pick Fill Seal Machines are great for packaging medicines. They fill things very accurately, making sure each package has the right amount. This is important because even small mistakes can be bad for patients.

These machines can handle many different kinds of medicines, from pills to powders. So they’re very useful for medicine packaging companies.

Maintaining Sterility and Product Integrity

The packaging of pharmaceuticals must be done in a way that keeps the product safe and free from germs. Pick Fill Seal Machines are great for clean environments.

They help prevent contamination. These machines are automated. They follow strict hygiene rules. This is important in pharmaceutical production.

Sterile products need extra protection. Premade Pouch Pick Fill Seal Machines are perfect for this. These machines use pre-sterilized pouches.

They fill and seal them in a clean room. This keeps the products sterile throughout the packaging process.

Enhancing Efficiency and Production Output

Pick Fill Seal Machines can significantly speed up pharmaceutical production. They can handle many products very fast.

This helps companies meet the growing need for products. They can do this without losing quality.

These machines are also small, which saves space in factories. The process is simpler and has fewer mistakes because it combines several steps.

Adaptability to Various Pharmaceutical Packaging Needs

Pick Fill Seal Machines can pack many things, like bottles, vials, pouches, and blisters. This is great for medicines, as different ones need different packaging.

Consumers want products that are convenient, sustainable, and safe. Pick Fill Seal Machines can help with this in pharmaceutical packaging.

Suggested Read:

Factors to Consider When Choosing a PFS Machine

Choosing the right Pick Fill Seal machine for your pharmaceutical packaging is important. It can affect how fast you make products, how good they are, and how much it costs to run your business. Let’s talk about what to think about when choosing one.

Production Capacity and Speed

The machine’s speed and how much it can produce are important factors. Your PFS machine should be able to handle your current work and be ready for more in the future. Check your packaging needs carefully.

The machine should produce the right amount without going too fast or too slow. This balance is important for making good-quality medicine and running your company efficiently.

Flexibility and Adaptability

The pharmaceutical industry needs packaging for many different products. Choose a PFS machine that can handle different sizes, shapes, and materials.

A flexible machine that can work with many packaging formats is very useful. This is especially true if your products will change or grow in the future.

Ease of Operation and Maintenance

The machine should be easy to use. Look for a Premade Pouch Pick Fill Seal Machine that is user-friendly. It should also be easy to clean and maintain.

Machines with simple cleaning processes and quick-disconnect features can help you avoid downtime.

Automation and Digital Capabilities

Today, automation can really help your packaging. Look for machines with smart controls and touch screens. They should be able to handle different batches.

These features will help you package things more accurately and quickly. You’ll also get helpful data.

Compliance with Industry Standards

The PFS machine should have ISO certification or other relevant quality standards. This is important in the pharmaceutical industry, where strict rules apply to packaging.

A machine that meets these standards will help you follow the rules and make safe products. By considering these factors, you can choose a PFS machine that fits your needs now and in the future.

Pick Fill Seal Machine FAQs: Your Top Questions Answered

What is a Pick Fill Seal Machine?

An FFS machine is a packaging machine. FFS machines are used in pharmaceutical packaging. A Pick Fill Seal machine is used to package pharmaceuticals. It picks pouches, fills them, and seals them. These machines are important for medicine packaging companies. They help with efficiency and product quality.

How does a Pick Fill Seal Machine work?

The machine picks up empty pouches. The filling system puts the product into the pouches. The pouches are sealed. This process is fast and makes many pouches. It is good for packaging medicines.

What are the advantages of using a Pick Fill Seal Machine?

Pick Fill Seal machines are efficient and fast. They make products consistently. They can handle different products and packaging. They are clean and affordable. They help pharmaceutical companies protect their products. They make products last longer. They follow strict industry rules.

Are there different types of Pick Fill Seal Machines?

There are different types of Pick Fill Seal Machines. Some are called VFFS, HFFS, and Premade Pouch. Each type is for different products and packaging. Premade Pouch is good for medicines. It uses pouches that are already clean.

What should I consider when implementing a Pick Fill Seal Machine?

A Pick Fill Seal Machine should be chosen carefully. Consider your product, how much you need to make, and what kind of packaging you’ll use. Make sure the machine can handle your specific needs. Train your workers to use the machine properly. Keep the machine in good condition to avoid problems.

Conclusion

Pharmaceutical packaging is important for drug safety. Pick fill seal machine is a big improvement. They’re precise, fast, and keep things clean. Use these machines to make your packaging better. This will improve your products and keep patients safe. AdroitMachinery provides efficient packaging solutions for pharma and other industries.

Rules are changing, and customers want more. You need to use new packaging methods. Pick fill seal machines can help you do this. They’ll make your packaging better now and in the future. Are you ready to be a leader in pharmaceutical packaging?