The food and beverage industry is highly competitive. To succeed, companies need more than just good food. They also need to be efficient, accurate, and flexible. A Pick Fill Seal machine (PFS) can help. It picks, fills, and seals products quickly and accurately, while keeping things clean.

PFS machines can help businesses save money. They can also reduce waste. This can lead to increased productivity. Whether you’re a small business or a big one, understanding PFS machines can help you succeed.

Let’s learn more about why PFS machines are the future of packaging. But..but…but…if you want all of this information in pdf form for pick fill seal machine – check the image text. If you directly wanna know about a filling sealing machine contact us today at AdroitMachinery a Pouch packing machine manufacturer.

What is a Pick Fill Seal Machine?

A PFS machine is a special piece of equipment that automates the packaging process. It’s especially useful in the food and beverage industry. But what exactly does it do?

Definition

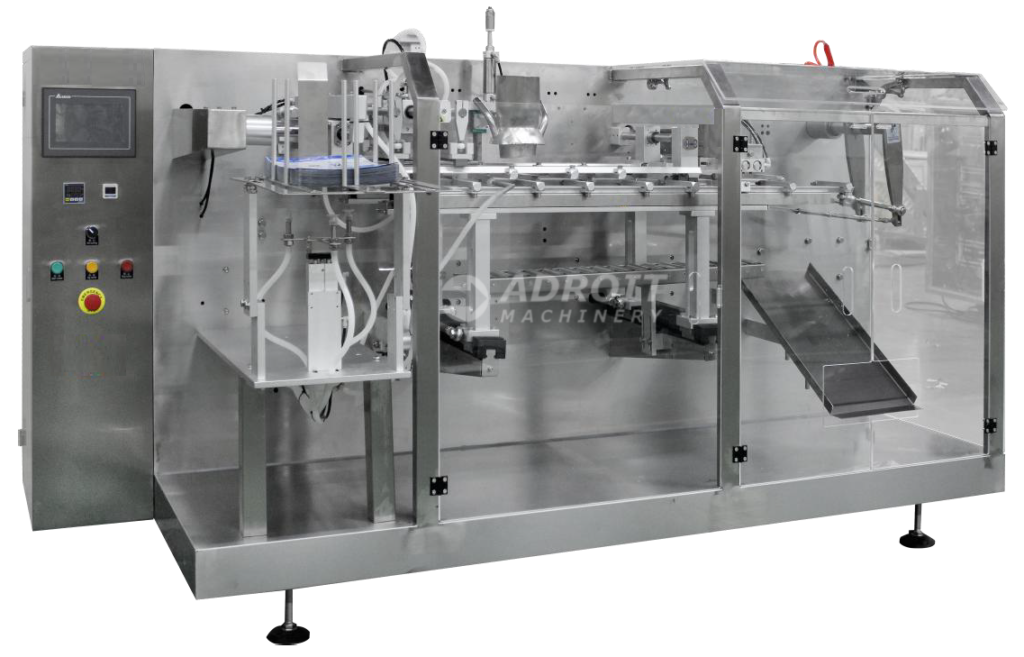

A PFS machine does three main jobs. First, it picks up empty containers. Then, it fills them with the right product. Finally, it seals them closed. This simple process helps keep things moving quickly and smoothly in busy factories.

Key Components

- Pick-and-Place System: The machine uses robots to pick up containers. The robots put the containers on the line. This makes sure the containers are ready to be filled.

- Filling Mechanism: The machine fills each container with the correct amount. It works for liquids, powders, and solids, and always puts the same amount in each one. This helps to avoid waste and makes sure all products are the same.

- Sealing Unit: After filling, the containers go to the sealing station. There, they are sealed shut. This keeps the food fresh and clean. The sealing method depends on the packaging. It can be heat sealing, ultrasonic sealing, or adhesive sealing.

How It Works

The PFS machine operates in a seamless, automated loop:

- Picking: The machine picks up empty containers from a pile or belt.

- Filling: We fill the containers with the product. We make sure to put in just the right amount. This helps us avoid putting too much or too little.

- Sealing: The containers are filled. After sealing, they become tamper-proof and hygienic. These packages are now ready for distribution.

Suggested Read:

Industry Applications of Premade Pouch Pick Fill Seal Machine

PFS machines are very useful in the food and beverage industry. Many different parts of this industry use these machines. Here’s how they help:

Dairy Products

Dairy products need to be packaged with precision and hygiene. PFS machines are great for packaging dairy products. They can package yogurt, milk, cheese, and cream. PFS machines can handle both liquid and semi-solid products. This makes them perfect for packaging dairy products. PFS machines fill products consistently. This is important for products sold by volume. They also seal the packaging tightly. This helps keep the products fresh and lasts longer.

Beverages

Beverage makers use PFS machines to package their drinks. These machines are fast and can fill many bottles. They can also fill different kinds of containers, like bottles, boxes, and pouches. The machines fill the bottles correctly, so no drink is wasted.

Ready-to-Eat Meals

The convenience food industry, especially ready-to-eat meals, is growing fast. PFS machines are important for packaging these meals. They can package meals with many parts, like pasta, salads, or pre-cooked dishes. These machines keep the meals safe and look good. They also seal the meals to keep flavors in and prevent leaks. This makes the meals ready to be shipped and stored.

Snacks and Confectioneries

PFS machines package snacks and confectioneries. They preserve products, help with branding, and attract customers. These machines can handle many snacks, like chips, nuts, candies, and chocolates. They use various packaging materials, like plastic, foil, and paper. This lets businesses meet different branding and sustainability goals.

PFS machines fill and seal packages accurately. This ensures each package has the right amount of product, building customer trust.

PFS technology is always improving. New technologies are making these machines better and more capable:

Integration with IoT

The Internet of Things (IoT) is changing how things are made. PFS machines are part of this change. New PFS systems can connect to the internet. This helps us see what the machines are doing. We can use this information to make factories work better.

Sustainability Features

Sustainability is important to businesses and consumers. PFS machines are becoming more eco-friendly. Many new models use recyclable and biodegradable materials. This helps companies protect the environment. These machines also use less energy. This saves money and reduces pollution. These features are good for the food and beverage industry.

Automation and AI

AI is changing PFS technology. It’s making things more automatic and easier to control. AI machines can learn from mistakes and get better at their jobs. They can fill things perfectly and waste less. AI can also predict when machines might break and fix them before they do. This saves money and keeps things running smoothly.

Advanced Control Systems

Modern PFS machines have better control systems. These systems make the machines more precise and flexible. You can control the machines with touchscreens, remote controls, and advanced software. These systems make it easy to change settings, solve problems, and get more out of your machines. With better technology, we’ll get even more user-friendly control systems for PFS machines.

Enhanced Customization

Customization is important for manufacturers to stand out and meet specific needs. PFS machines now offer more flexibility in packaging. Custom packaging can help with diverse product lines and brand identity. Manufacturers can now create unique packaging that matches their marketing and consumer preferences.

Suggested Read:

How to Choose the Right Pick Fill Seal Machine for Your Operations

Choosing the right PFS machine is important for your production. It can affect how fast you work, how much it costs, and how good your products are. Here’s how to choose the right one:

Assessing Your Needs

A PFS machine is a good investment if it meets your production requirements:

- Production Volume: Figure out how much product you need to package. If you need to package a lot quickly, use a big machine. If you need to package a little slowly, use a small machine.

- Product Type: Consider the type of product you’re packaging. Some PFS machines are for liquids, some for powders, and some for solids. Pick a machine that’s right for your product.

- Packaging Requirements: Choose the packaging you’ll use. PFS machines can handle different kinds of packaging, like pouches, bottles, and cartons. Pick a machine that works with your packaging choice.

Budget Considerations

Cost is a significant factor in choosing the right PFS machine:

- Initial Investment: Machines with more features are usually more expensive. But they can save you money in the long run. Weigh the cost against the benefits.

- Operational Costs: Consider the long-term costs of the machine. Think about energy use, upkeep, and extra parts. Choose machines that save energy and need less maintenance.

Vendor Reputation

The supplier you choose can significantly impact your experience with the PFS machine:

- Experience and Expertise: Choose a vendor with experience in the industry. Look for a vendor with a good reputation. They can help you pick the best machine.

- Customer Support: Good customer service is important. Find a vendor who can help you train your team. Look for a vendor who can fix problems quickly. Choose a vendor who can keep your system running smoothly.

Future-Proofing

Technology is always changing, and production needs do too. It’s important to choose a machine that can adjust to future demands:

- Upgradability: Look for machines that can be upgraded or expanded. This might involve adding new features. It could also mean using better technology or trying different packaging materials.

- Flexibility: Choose machines that can handle different products and packaging types. This flexibility helps you adapt to changing market trends and consumer preferences. You won’t need to invest in new equipment as often.

Suggested Read:

Success Stories: Companies Thriving with Pick Fill Seal Machines

Real-world examples show how Pick Fill Seal (PFS) machines can be beneficial. Here are three success stories from the food and beverage industry. These examples highlight how PFS machines have improved operations:

Case Study 1: Dairy Producer Scaling Up

Company: FreshDairy Inc.

Challenge: FreshDairy Inc. is a growing dairy producer. They faced challenges with manual packaging, which slowed production and caused quality issues. They needed a solution to handle increased production volumes. They also wanted to maintain high hygiene standards.

Solution: FreshDairy Inc. bought a high-capacity PFS machine for dairy products. This machine improved the packaging of yogurt and milk. It automates the entire process, from filling to sealing.

Results:

- Increased Production Speed: The new PFS machine sped up production. FreshDairy could now meet higher demand without hiring more workers.

- Improved Product Consistency: The PFS machine fills and seals products precisely. This consistency in quality improves customer satisfaction.

- Enhanced Hygiene: The machine operates automatically, which reduces the need for human contact. This helps improve hygiene and meet strict food safety standards.

Case Study 2: Beverage Company Reducing Costs

Company: PureRefresh Beverages

Challenge: PureRefresh Beverages is a major player in the soft drink market. They faced high production costs because of manual filling and packaging. To lower costs and boost efficiency, they needed a better solution.

Solution: The company introduced a new PFS machine. It can handle different types of beverages, like carbonated drinks and juices. The machine features automated filling controls and adjustable sealing options.

Results:

- Lower Operational Costs: Automation cut labor costs and reduced material waste. This led to big savings.

- Higher Production Efficiency: The PFS machine worked faster and more accurately. This improved overall production efficiency. PureRefresh could then scale up operations without extra costs.

- Consistent Quality: The precise filling mechanisms kept the product quality consistent. They also lowered the chances of spillage and contamination.

Case Study 3: Snack Manufacturer Enhancing Product Presentation

Company: SnackMasters Ltd.

Challenge: SnackMasters Ltd. needed a way to package different snacks like chips, nuts, and candies. They wanted to make their packaging look better and simplify their production process.

Solution: SnackMasters invested in a PFS machine with customizable packaging options. “The machine can handle various materials. It works with foil pouches and plastic bags.

Results:

- Improved Packaging Appearance: SnackMasters used different packaging formats. This improved product presentation and matched their branding strategies.

- Streamlined Production: Automation made packaging easier. It cut down on both the time and labor needed for production.

- Increased Flexibility: The machine was very versatile. It allowed SnackMasters to quickly switch between different products and packaging styles. This helped them manage their wide range of products.

Suggested Read:

Conclusion

The Pick Fill Seal (PFS) machine is a major step forward in packaging for the food and beverage industry. It automates picking, filling, and sealing. This helps to improve production lines and makes everything run more efficiently.

PFS machines boost efficiency and accuracy while enhancing hygiene and cutting costs. They can handle various products and packaging types. This makes them flexible and able to adapt to changes in the industry.

Technology is evolving, and PFS machines are keeping up. They now include features like IoT connectivity, eco-friendly options, and AI-driven automation. These advancements make them even more valuable for manufacturers.

Investing in a Seal Packing Machine can significantly improve your packaging process. To see how PFS technology can benefit you, contact experts or suppliers. They can provide solutions tailored to your needs.

If you have questions about the fill seal packing machine, feel free to reach out for efficient packaging solutions at AdroitMachinery. Embrace the future of packaging and enhance your business’s efficiency and productivity.

FAQs about Pick Fill Seal Machine

Q: What maintenance is required for a Pick Fill Seal machine?

A: Regular maintenance for a PFS machine involves cleaning and checking for wear and tear. Make sure all parts are working properly. Inspect the machine regularly. Follow the manufacturer’s guidelines. This will keep the machine running smoothly.

Q: Can a Pick Fill Seal machine handle multiple product types?

A: Yes, many PFS machines are versatile. They can handle different products, including liquids, powders, and solids. Make sure the machine you select works with the specific products you want to package.

Q: How can I determine the right PFS machine for my needs?

A: Evaluate your production volume, product type, and packaging needs. Think about your budget, the reputation of vendors, and future growth. Talk to industry experts or suppliers for advice on choosing the right machine.

Q: What are the latest trends in Pick Fill Seal technology?

A: Recent trends include using IoT for real-time monitoring. There are also new features for eco-friendly packaging. AI-driven automation is improving efficiency. Advanced control systems are enhancing the user experience. Additionally, there are more options for customizing packaging.