Investing in a quality liquid packaging machine can change your production line. This machine fills and seals liquid products accurately. It boosts productivity and cuts waste. In this article, we will explore ten key benefits of this investment. Boost efficiency with this machine. Improve product quality. Learn why this is essential for your business.

What is a Liquid Packaging Machine?

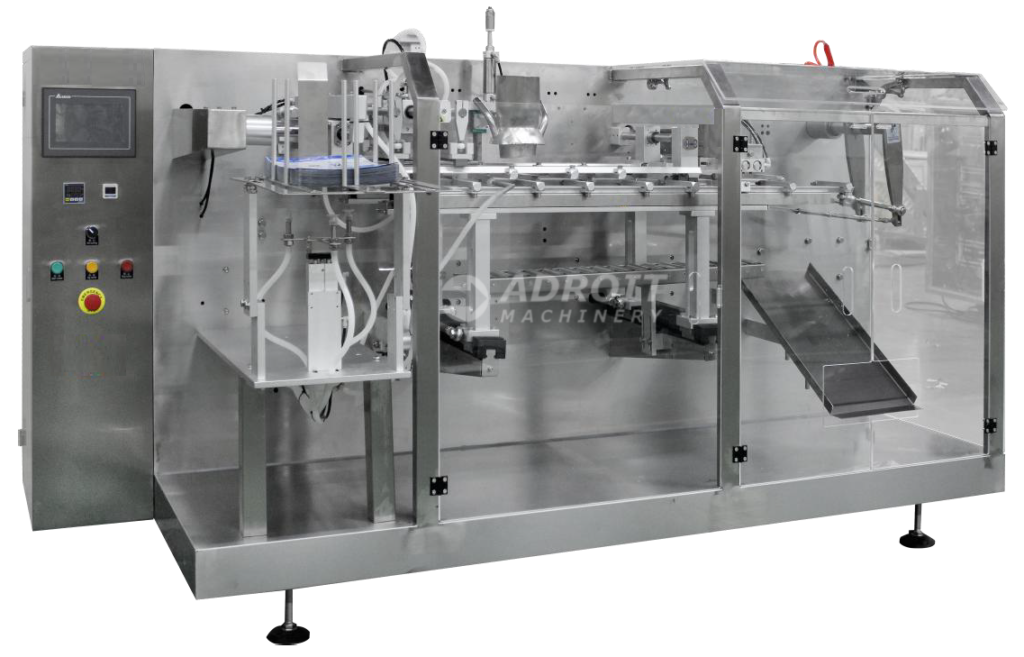

A liquid packaging machine is a device used to fill and seal containers with liquid products. These machines are vital in many industries. They include food, beverages, cosmetics, and pharmaceuticals. They package liquids efficiently and safely. This keeps the product quality and consistency.

An automatic liquid packaging machine makes the process easier. They fill and seal packages automatically. This reduces the need for manual labor, increases speed, and minimizes errors. Liquid shampoo sachet packaging machines pack shampoos in small, single-use sachets. These machines fill each sachet accurately. They seal them tightly to stop leaks.

Another type is the liquid foam packaging machine. It is used for products like soaps and detergents that are foamy. These machines are made to handle foam well. They ensure the packaging keeps the product’s quality.

Investing in a high-quality liquid packaging machine can significantly boost your production efficiency. It reduces waste, enhances product quality, and ensures a consistent output. You might need an automatic liquid packaging machine. Or, you could need a shampoo sachet packaging machine. Another option is a foam packaging machine. These machines are crucial for businesses aiming to improve their packaging process.

10 Benefits Of Investing A Liquid Packaging Machine

Boost your production with a high-quality liquid packaging machine. These machines offer many benefits. They increase speed and reduce waste. They improve consistency and lower labor costs. They also enhance safety. Get ready for faster turnaround times, happier customers, and a healthier bottom line.

Fulfill Growing Needs with Ease

The process industries are always changing. Consumers want more convenience and variety. Liquid packaging machines help businesses keep up. Imagine your liquid syrup plant faces a sudden surge in demand. A good liquid packaging machine lets you quickly boost production. These machines can handle different packaging types. They work for single-serve drinks, pre-measured laundry detergent pouches, and shampoo packets. They help you meet customer needs without sacrificing quality or efficiency.

Automating packaging also frees up labor for other tasks. This boosts productivity. It also cuts down on manual work. This is important when finding skilled workers is tough. Top liquid packaging machine manufacturers offer various models for different needs and budgets. If you want to grow your business, A liquid packaging machine is a smart choice. It helps you meet different needs and boost production.

Suggest Read:

- The Definitive Guide to Oral Liquid Manufacturing Plant

- 8 Strategies for Growing Your Income with a Liquid Manufacturing Plant

Reduced Labor Costs

Investing in a liquid packaging machine can cut labor costs significantly. It reduces the need for manual work and saves money. Manual filling and sealing of liquids is a time-consuming and error-prone process. Think about the work needed in a liquid syrup plant. It fills thousands of bottles every day. Liquid packaging machines eliminate this need for manual intervention. They automate the entire filling, sealing, and labeling process, requiring minimal operator oversight.

This lets your team focus on more important tasks. They can work on quality control or equipment maintenance. Even for smaller operations, a semi-automatic machine can significantly reduce labor needs. A sachet liquid shampoo packaging machine speeds up production. It works faster than filling packets by hand. It cuts down on the need for manual work. This reduces payroll costs and saves time for your team. Overall, it makes your operations more efficient and productive.

Cut Down on Waste and Rejects

Manual filling of liquids can cause overfilling, underfilling, and damaged containers. This leads to a lot of rejected products. For example, a leaky shampoo pouch or an overflowing syrup bottle can hurt your profits. Liquid packaging machines fix these problems. They ensure accurate and consistent filling every time. These machines use advanced metering systems to dispense the right amount of product. This reduces mistakes like overfills and underfills.

They also have automated sealing to prevent leaks and spoilage. By cutting down on waste and rejects, these machines help save money. They also support a more sustainable operation. Top liquid packaging machine makers focus on efficiency and reducing material waste. Investing in a liquid packaging machine can boost your margins. It can also increase your profits. It is also environmentally friendly.

Proactive Quality Management

Consumers want consistency and safety from the liquids they buy. This applies to cleaning products and personal care items. If there is a quality issue with your liquid syrup, it can damage your brand and lead to costly recalls. Liquid packaging machines help you manage quality better. They work well with various quality control systems. For example, you can add metal detectors to catch any foreign particles. Their filling mechanisms are precise.

This helps reduce volume inconsistencies. Each pouch or bottle meets your standards. Many machines also offer real-time monitoring and data analysis. This helps you spot and fix problems before defective products reach customers. Liquid packaging machines automate quality control. This keeps your brand protected. It also ensures your products are safe and high-quality.

Boosted Production Capacity and Maximize output

Whether you run a small beverage company or a large liquid soap plant, boosting output is crucial. Liquid packaging machines can greatly help. They fill and seal containers at high speeds. This is much faster and more accurate than manual filling. For a liquid soap plant, using a high-speed machine can fill many more bottles each hour. It can increase the number of bottles filled by thousands.

This helps you handle increased demand easily. Automation lets your team focus on other tasks. It also helps them manage more machines. This increases overall production. Investing in a liquid packaging machine is a smart move to grow your business.

Suggest Read:

- End Pet Food Packaging Headaches: Efficient Solutions for Your Business

- Achieve Food Packaging Success with Adroit Machinery

Workplace wellness and safety at work

Creating a safe and healthy work environment is not just an ethical duty; it’s good for business too. Liquid packaging machines can help with this. Manual liquid filling can be tough on workers. It often leads to repetitive strain injuries and fatigue. Lifting heavy containers and reaching awkward positions can harm worker well-being. Liquid packaging machines automate this process. This reduces physical strain and makes work less tiring.

Operators manage the machine instead of doing the heavy lifting. The machines also reduce the risk of spills and splashes. This keeps your team safe from burns and exposure to harsh chemicals. Liquid packaging machines make the workplace safer. They also make it more comfortable for workers. This leads to better health and job satisfaction. This, in turn, benefits your business.

Gain a competitive edge

Liquid packaging machines can set you apart from your competitors. They offer many benefits that can strengthen your market position. First, they automate packaging, speeding up production and increasing output. This helps you meet market demands quickly and deliver products faster. Second, these machines ensure consistent quality and precise filling.

This reliability builds consumer trust and brand loyalty. Third, they reduce waste and lower labor costs. This boosts your profit margins. It also allows you to invest in research or offer competitive prices. Liquid packaging machines can improve your operations. They help you deliver a better product and control costs. They are a smart investment. They help you gain an edge over your rivals.

Empowering Workers Through Automation

Automation isn’t about replacing workers. It’s about empowering them. Liquid packaging machines are a good example. Some might see them as a job threat, but they help your team. Workers no longer spend hours filling bottles. They can watch the machine. They can check quality. They can also handle tasks that need human skills, like fixing problems. This boosts efficiency and improves employee morale.

Repetitive work can be tiring and lead to injuries. Liquid packaging machines do the tough work. They make the job safer and more interesting. Workers can also learn to program and maintain the machines, gaining new skills. Liquid packaging machines can improve your production line. They also help keep your team engaged.

Next-Level Social Distancing

Keeping your workforce safe is very important. Liquid packaging machines help promote social distancing. They make it easier to keep workers apart on the production line. Manual filling requires workers to be close together, which can be risky. Liquid packaging machines automate the process. Workers don’t need to handle the product directly.

Operators can monitor the machine and check quality while staying apart. This reduces contact between workers and lowers the risk of spreading viruses. Plus, these machines let you run with fewer people. This makes your workplace safer. If you want to boost production and keep your team safe, liquid packaging machines are a great choice.

Greater use of Floor Space

In the process industries, floor space is very valuable. You need to use every square foot efficiently to boost production. Liquid packaging machines can help save space. Manual filling lines need separate workstations and big equipment. In contrast, liquid packaging machines are compact. They combine filling, sealing, and sometimes labeling into one unit.

This saves space for other uses, like storage or extra equipment. For example, in a beverage bottling plant, switching from a manual line to a liquid packaging machine can save space. This extra space might allow for another bottling line. This could double your output without needing a bigger facility. If you want to use your space better and increase production, liquid packaging machines are a great solution.

What is the Purpose of a Liquid Packaging Machine?

Imagine a machine that fills bottles, pouches, or cartons with your liquid product. It’s hardworking and efficient. It seals them tightly and ensures a consistent output every time. That’s the magic of a liquid packaging machine. These machines are vital for many industries. They are used by food and drink companies, chemical makers, and drug manufacturers.

Here’s a breakdown of their key purpose:

- Filling: Liquid packaging machines accurately dispense your product into various containers. They can handle many types of liquids. This includes thin and watery ones. They can also manage thick liquids like shampoos and creams.

- Sealing: After filling, the machine seals the containers. This keeps them from leaking, spilling, or getting contaminated. This ensures a tamper-evident and safe product for consumers.

- Automation: Modern liquid packaging machines are highly automated. This means operators need to do less. As a result, production is more efficient and consistent.

- Versatility: Different machines cater to diverse needs. For example, a machine for single-serve juice boxes is different from one that fills large containers of laundry detergent.

How do I choose a Liquid Pouch Packing Machine?

Choosing the right liquid pouch packing machine isn’t the same for everyone. What works for one operation might not work for another. The perfect machine will depend on your specific needs and product characteristics.

Here are some key factors to consider:

- Your Product: What are you filling? Thin liquids, such as juices and syrups, need different machines. Thick liquids, like shampoos and sauces, need other machines. Consider the viscosity, abrasiveness, and compatibility of your product with the machine’s materials. For example, a plant making liquid oral syrups may need a machine with special features. These features help handle different medications.

- Pouch Format: What kind of pouches do you envision? Stand-up pouches, pillow pouches, or perhaps gusseted pouches? Each format requires a compatible machine with specific sealing and filling mechanisms.

- Production Speed: How much product do you need to fill per minute or hour? Match your machine’s speed to your production goals. A high-speed machine may be too much for a small operation. On the other hand, a slow machine might slow down production in a larger plant, such as one making liquid syrup.

- Automation Level: Do you require a fully automatic machine or a semi-automatic option? Automatic machines offer maximum efficiency but require a higher initial investment. Semi-automatic machines are good for small operations. They work well when products change often.

- Budget: Liquid pouch packing machines come in a variety of price ranges. Set your budget first. Then, choose the features that matter most for your needs.

Beyond these core factors, consider additional features that might be beneficial:

- Coding and Printing: Does your pouch require printed expiration dates or lot codes? Look for machines with integrated printing options.

- Cleaning and Maintenance: Choose a machine that is easy to clean. This will help reduce maintenance time and keep your machine running smoothly.

- Safety Features: Safety should be a priority. Ensure the machine has emergency stop buttons and proper safety guards.

Why Choose Adroit Machinery for Liquid Packaging Machine?

Choosing the right liquid packaging machine is crucial for process industries. If you run a plant that makes liquid products, like oral solutions or soap, you need efficiency. You also need reliability. Both are essential for smooth operations. Adroit Machinery is the perfect partner for your liquid packaging needs:

- Deep Industry Knowledge: Our team goes beyond selling machines. We are experts in the process industries. We understand the challenges you face. We handle details for delicate pharmaceuticals. We also manage leak-proof liquid soap containers. We offer personalized consultations. We can recommend the best machine for your product, production line, and budget.

- Uncompromising Quality: At Adroit Machinery, we never compromise on quality. Our machines use strong, high-quality materials. They feature the latest technology. This means they last longer and have less downtime. You’ll get consistent, reliable packaging for many years.

- Tailored Solutions: We understand that every operation has unique needs. We offer a range of liquid packaging machines. Our high-speed, fully automatic models are great for large-scale production. We also have user-friendly semi-automatic machines for smaller batches and frequent product changes. We also offer customization options to fit your needs. Imagine a machine designed for your syrup plant. It fits perfectly with your current filling line. It handles the thickness of your syrups well.

- Long-Term Support: Our commitment goes beyond the sale. We offer full after-sales support. This includes installation and training for your operators. We also provide spare parts when needed. Our team is here to help your machine run smoothly and efficiently. We aim to minimize any disruptions to your production schedule.

- Focus on Efficiency: At Adroit Machinery, we know that efficiency is key to your success. Our machines make liquid packaging easier. They help reduce waste and boost output. This means you get more production, lower costs, and better profits.

Conclusion

Get a great liquid filling machine! It works faster, saves money, and keeps your product perfect. Adroit Machinery makes them with the latest tech and helps you set it up easily. Plus, it keeps your workers safe and saves space in your factory. Faster filling, lower costs, happier workers!