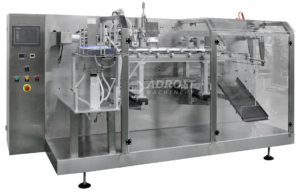

Protein Milk Powder Filling Packing Machine for Premade Zipper Bag

At Adroit Machinery, a reputable manufacturer specializing in Pharmaceutical, Food & Beverages, Pesticides Processing, and Primary packaging machinery, we are excited to present our Protein Milk Powder Filling Packing Machine for Premade Zipper Bag.

This cutting-edge machine is designed to streamline the packaging process for powdered products, providing a seamless and efficient solution for your packaging needs. With its advanced features and customizable options, this machine ensures accuracy, convenience, and exceptional packaging results.

Main Function:-

The Protein Milk Powder Filling Packing Machine automates the entire packaging process for powder products, including feeding, weighing, bag opening, filling, sealing, and date printing. With this machine, you can achieve consistent and reliable packaging, eliminating the need for manual intervention and optimizing your production line.

Application:-

Our machine is suitable for a diverse range of powder products, including but not limited to:

- Corn flour

- Spices

- Milk powder

- Coffee powder

- Medical powder

- Chemical powder

- And more

Optional Bag Types:-

The machine is compatible with various premade pouches, providing flexibility in packaging options. It supports the following types of premade bags:

- 4 side seal bags

- Doypack bags with zippers

- Standup bags

- M shape gusset bags

- And more

How we can benefit your business

Machine Description:-

Auger Filler Metering System:

Equipped with an auger filler metering system, our Protein Milk Powder Filling Packing Machine ensures precise and consistent filling of your powdered products. The machine features an automatic feeding conveyor and offers different sizes of auger fillers, catering to a wide range of metering requirements for powder products.

Main Machine Process:-

Our machine undergoes a well-designed process to ensure efficient and reliable packaging. From bag pickup and date printing to bag opening, filling, bag arranging, sealing, and output, each step is seamlessly integrated for a fully automated operation. This comprehensive process saves time and enhances productivity.

Main Machine Features:-

- We offer different machine models to accommodate a wide range of premade bag sizes, ensuring compatibility with your specific packaging requirements.

- The main machine structure can be customized to accommodate various bag shapes, including doypack zipper bags, 4 side seal bags, standup bags, irregular bags, and more. This customization ensures a perfect fit for your unique packaging needs.

- Our machine incorporates multiple working stations to facilitate a fully automatic process, covering bag pickup, date printing, bag opening, filling, bag arranging, sealing, and output. This efficient workflow minimizes human intervention and maximizes overall productivity.

- With an upgraded PLC control system, our machine is easy to operate through the user-friendly touch screen interface. The intuitive parameter setting options enhance usability and simplify operation for your staff.

- The machine can be equipped with different metering systems, such as a multihead weigher, liquid pump, auger filler, or bucket chain, depending on the specific requirements of your powder products. This versatility ensures accurate and efficient filling and packing in premade pouches.

Parameter:-

We offer a range of models for the Protein Milk Powder Filling Packing Machine, allowing you to select the ideal machine to meet your unique packing sizes and production demands.

| Model | AM-210 | AM-260 |

|---|---|---|

| Bag Width* | 90 to 210mm | 150 to 260mm |

| Bag Length* | 110 to 330mm | 150 to 400mm |

| Packing speed** | Up to 40 bags/min | Up to 40 bags/min |

| Power | 4KW 50Hz | 4.5KW 50Hz |

| Voltage | 440V | 440V |

| Air consumption | 0.5m³ | 0.7m³ |

| Suitable to fill | Liquid, Powder, Granule, Paste with different filling system | |

| Station* | 6 to 8 | |

| Type Of Pouch | Premade pouches Three Side Seal Stand-Up Pouch Zipper Pouch Spout pouch | |

| Material | Product contact area is Stainless steel [SS304/SS316] Other area is Stainless steel, Aluminum etc. Lower structure inside is mild steel with painted | |

Note: Machine parameters can be customized according to your specific packaging requirements.