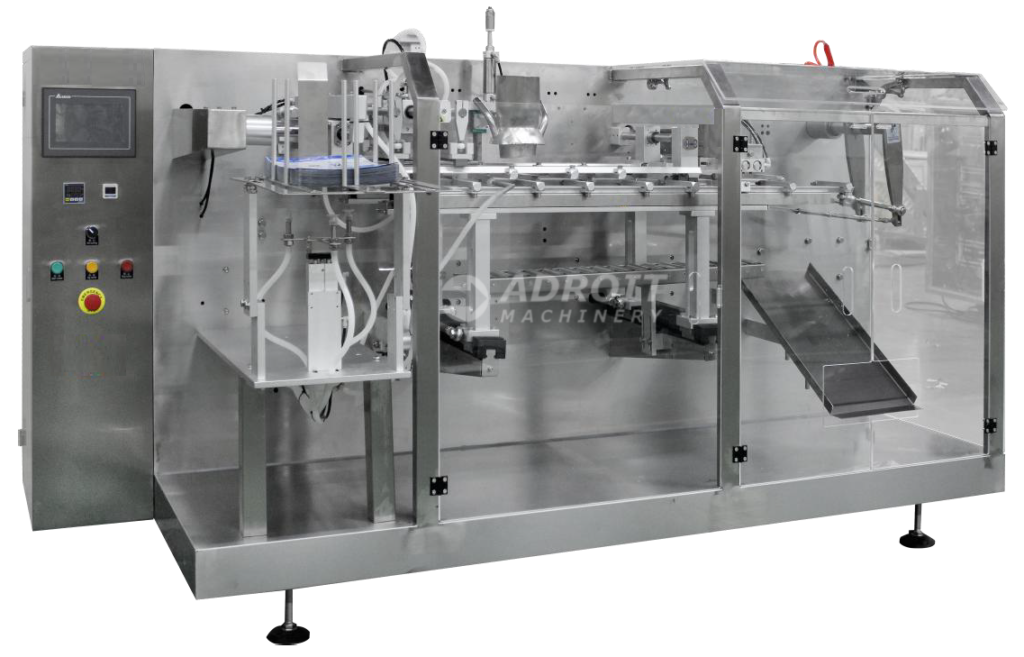

premade pouch pick fill seal machine

Why Choose PREMADE POUCH PICK FILL SEAL MACHINE?

A premade pouch packaging machine packs products into ready-made bags. It’s very automated and can do many things. The machine does several steps on its own: It takes empty bags from a holder, It fills the bags with the right amount of product, It seals the bags to keep them safe.

- 10+ Years of Experience.

- Export to Over 130 Countries.

- Regional After-Sales Assistance.

Request a Demo for Our premade pouch pick fill seal machine Today!

How does an automatic pouch packing machine work?

The automatic standby premade pouch pick fill seal machine machine have 3 steps:

Pouch Handling

The machine picks pre-made pouches from a magazine or feeder.

Filling

The product is accurately filled into the pouch using various filling mechanisms.

Sealing

Once the pouch is full, it's sealed shut with heat. This is hard to open cleanly.

Applications of the premade pouch pick fill seal machine

The premade pouch pick fill seal machine—also known as a pouch packing machine—is widely used across various industries, including:

The food and beverage industry loves automation in packaging. Pick fill seal machine makes packaging easier and more efficient. These machines fill and seal products correctly. They handle all sizes, from single servings to large containers. They package products with precision. This helps keep food fresh and reduces waste.

Personal Care Packaging Solutions

Fill seal packing machine automated systems that package products. They are used for many things, including personal care products. These machines help companies work faster and save money. They also make sure products are good quality.PFS machines are very versatile. The sealing mechanism is strong and reliable.

Packaging automation helps the pharmaceutical industry. Pick fill seal machine is important for packaging medicines and vaccines. These machines make sure the packaging is correct and clean. These machines keep the packaging under control. These machines help companies follow safety rules and track their products.

Our pets play a meaningful role in our lives from the first-morning stretch to the end of our day. They are like our family. We do a lot for our pets. We do everything they need to live their happy & healthy lives. We should always be aware of the products we use for them like pet food packaging.

Pouch Varieties: Premade Pouch Packing Machine

The Adroit Machinery automatic premade pouch packing machine is capable of producing plain and stand-up pouches in HFFS (Horizontal Form Fill Seal) machines, with options for or without a zipper and hanging hole. It can also create pouches with corner or center spouts, both plain and stand-up styles.

Key Features of Our PFS Machines

There are many benefits of Seal Packing Machine. Here are 5 benefits that you can’t avoid it:

Efficiency

PFS Machines can package faster, make more products, and need fewer people.

Accuracy

These machines fill and seal products. They make sure the products are clean.

Versatility

PFS machines can easily handle products like tablets, capsules, liquids, creams and more.

Hygiene

Usually, it is made of stainless steel for easy cleaning and maintaining cleanliness.

Reduced Material Waste

These machines are more efficient at using materials to make pouches.

Regulatory obedience

PFS machines monitor production. They keep records to meet regulations.

Pouch Pick Fill Seal MACHINE FEATURES

The automatic premade pouch pick fill seal machine has 8 features:

- Stainless Steel Construction.

- Simple, Clean, and Robust Design.

- Pouch Pickup by Vacuum Suction Cups.

- Pouch Detection before Filling.

- PLC Controlled Functionality.

- Digital Temperature Controller.

- Easy & Quick Pouch Change Over.

- Meet Electrical & Safety Standards.

MODEL TYPES

| Model | AM-210 | AM-260 |

|---|---|---|

| Bag Width* | 90 to 210mm | 150 to 260mm |

| Bag Length* | 110 to 330mm | 150 to 400mm |

| Packing speed** | Up to 40 bags/min | Up to 40 bags/min |

| Power | 4KW 50Hz | 4.5KW 50Hz |

| Voltage | 440V | 440V |

| Air consumption | 0.5m³ | 0.7m³ |

| Suitable to fill | Liquid, Powder, Granule, Paste with different filling system | |

| Station* | 6 to 8 | |

| Type Of Pouch | Premade pouches Three Side Seal Stand-Up Pouch Zipper Pouch Spout pouch | |

| Material | Product contact area is Stainless steel [SS304/SS316] Other area is Stainless steel, Aluminum etc. Lower structure inside is mild steel with painted | |

Note:

– we can give as per customer requirement.

– As per filling range and product.

PRE-MADE BAG PACKAGING SYSTEM

Pick Your Bags: Choose the right bag for your product—stand-up pouches, flat pouches, or zippered ones. The bag’s job? To protect your product and make it look good on the shelf.

Filling Time: The bags roll down the line, and the filling machine does its thing. Whether you’re pouring, scooping, or pumping, the right amount goes in every time.

Seal the Deal: Once filled, it’s time to seal ‘em up. Think of this as locking the treasure inside – using heat, glue, or pressure, the bags get sealed tight to keep everything fresh.

Inspect for Perfection: Before they move on, each bag gets a quick quality check. This step ensures no leaks, underfills, or missed labels—because we all know, no one wants a busted bag.

Label and Code: Here’s where the bags get their final touches—labels with all the important info: ingredients, expiration dates, and barcodes.

Pack and Ship: The filled and sealed bags are grouped together, boxed up, and shipped out. Whether they’re heading to a warehouse or straight to the shelves, they’re ready for action.

FAQS ABOUT PICK FILL SEAL MACHINE

A Pick Fill Seal Machine (PFS) machine is a packaging machine. It picks products, fills containers, and seals them. It is used in many industries, like food, medicine, and beauty.

In premade pouch pick fill seal machine, process typically involves:

Picking: The machine picks up products from a source. It uses robotic arms or other mechanisms. The source could be a conveyor belt or hopper.

Filling: The picked products are put into containers like pouches, bottles, or cartons.

Sealing: The containers are sealed to ensure product integrity and prevent contamination.

These are the some of the benefits of pick fill seal machine:

Increased efficiency: PFS machines can significantly improve packaging speed and accuracy.

Reduced labor costs: Automating packaging can help businesses use less manual labor.

Improved product quality: PFS machines ensure products are sealed consistently.

Enhanced flexibility:PFS machines are versatile. They can handle many different products. They can also handle different types of packaging.

When selecting a PFS machine, consider factors such as:

Product type: The machine needs to work with the products you’ll be packaging.

Packaging format: The machine should be able to handle pouches, bottles, or cartons.

Production volume: The machine’s capacity should match your production requirements.

Budget: Consider your budget when evaluating different PFS machine options.